X-ray Inspection

Precise Inspection of Electronic and Mechanical Components

Technical Data

| Part size | 800 x 500 mm |

| Max. part weight | 5 kg |

| Max. 2D scan area | 460 x 410 mm |

| Voltage range | 20 - 160 kV |

| Active detector area | 152 x 152 mm |

| Dynamic range | 16-bit |

| Lateral resolution | 0.9 µm |

| Detector rotation | ±70° |

| Target material | Tungsten |

| Max. target power | 15 W |

| Geometric magnification | ~3,000x |

| Total magnification | ~384,000x |

Operating Modes

- High-power mode for particularly dense materials

- Laminography for depth information reconstruction

Scope of Services

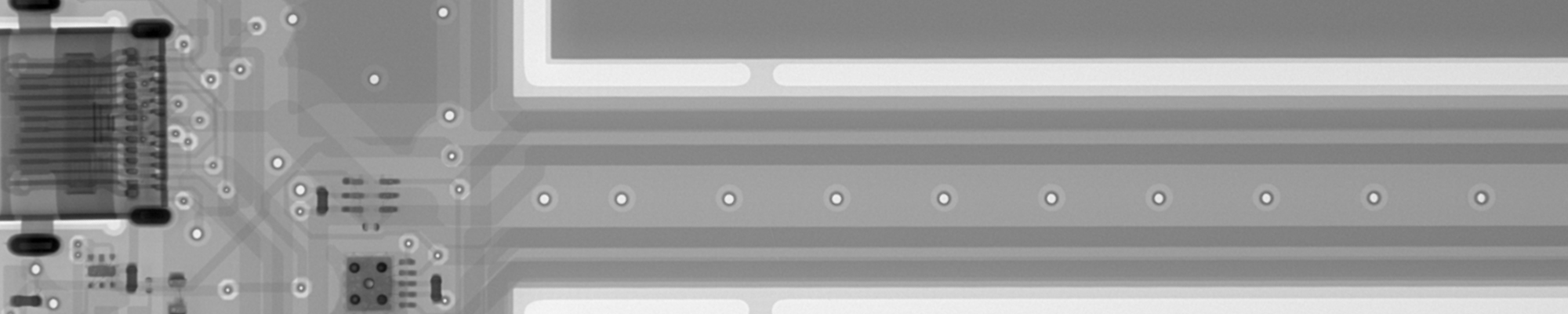

- X-ray Inspection: High-precision analysis of components to detect defects such as voids, cracks, delaminations, or insufficient solder joints.

- Laminography: Layer-by-layer examination of complex or multi-layer components, such as multilayer printed circuit boards or parts with hidden structures.

Typical Applications

- Inspection of printed circuit boards (PCBs), ICs, BGA components, and other electronic parts

- Identification of production defects or damage caused by thermal and mechanical stress

- Analysis of material structures and components made of metal, plastic, or composite materials

- Detection of manufacturing defects, cracks, or voids

Technical Equipment

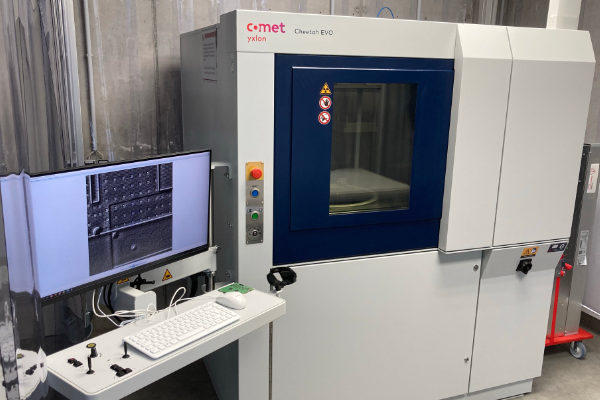

Our inspections are conducted using a Cheetah EVO from Comet Yxlon, a state-of-the-art X-ray system known for its excellent image quality and versatility. The system offers:

- High-resolution X-ray imaging: Precise detection of even the smallest defects in a wide range of materials.

- Laminography option: Enables layer-by-layer analysis of complex structures, such as multilayer PCBs or concealed components.

- Flexibility: Adaptable to various component sizes and inspection requirements.

The Cheetah EVO ensures that even demanding inspection tasks are performed reliably and efficiently.

Your Benefits

- Non-destructive testing: Analysis without damaging or altering the components.

- High precision: Detection of even the smallest defects and flaws.

- Flexibility: Suitable for inspecting a wide range of materials and component geometries.

Contact

For detailed information or to discuss your specific inspection requirements,

please feel free to contact us: