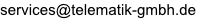

Thermal vacuum tests

Perfect preparation for extremes - thermal vacuum tests and thermal vacuum cycle tests

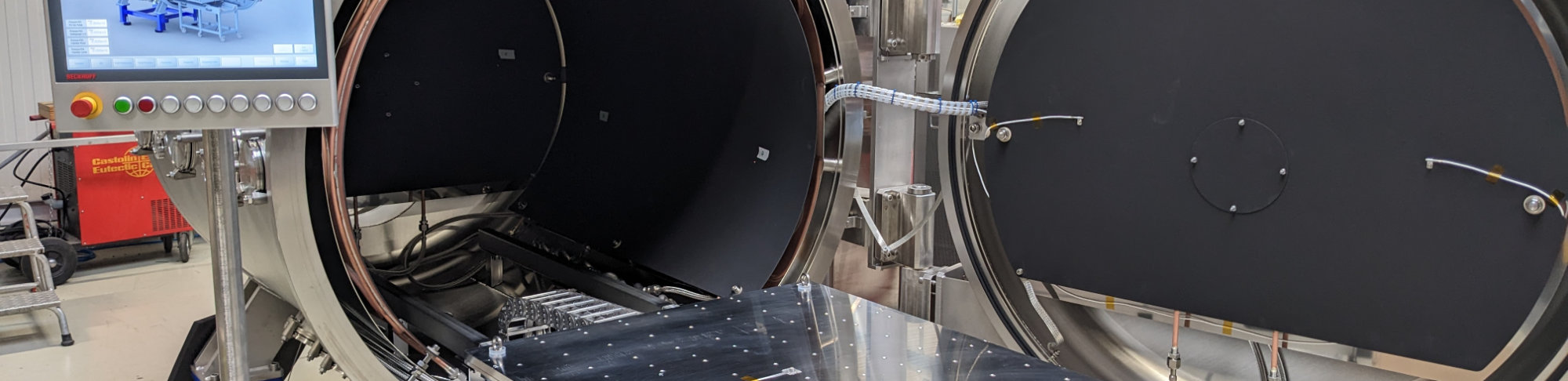

Technical Data

| Test Volume | 1200 x 900 x 800 mm |

| Max. Load Capacity | 150 kg |

| ————————— | ——————— |

| Vacuum System | |

| Pump-down Times | 10⁻⁴ mbar in 20 min |

| 10⁻⁵ mbar in 4 h | |

| Cooled Shroud | 10⁻⁷ mbar in +30 min |

| ————————— | ——————— |

| Temperature Control System | Liquid-based |

| Cooling Performance (Table) | Mechanical Cooling |

| Down to -70°C | |

| 100°C to -20°C | 2.3 - 2 kW |

| ~2°C/min | |

| -20°C to -40°C | 2 kW |

| ~1°C/min | |

| -40°C to -60°C | 1 kW |

| ~0.5°C/min | |

| -60°C to -70°C | 0.3 kW |

| ~0.1°C/min | |

| ————————— | ——————— |

| Cooling Performance (Shroud) | Mechanical Cooling |

| Down to -60°C | |

| 150°C to -60°C | 1.2 - 1.5 kW |

| ————————— | ——————— |

| Heating Power | Resistance Heating |

| Up to 150°C | |

| 3 kW | |

| >1°C/min | |

| ————————— | ——————— |

| Available Interfaces | |

| Temperature Measurement | 16 x Pt1000 |

| GPIO | 6 x Sub-D 25 Pin |

| Power Ports | 4 (max. 8A) |

| High-Frequency Ports (RF) | 4 x Type N (50Ω) |

Thermal vacuum test

How does your technology behave under extreme conditions? Our thermal vacuum test simulates environments with extreme temperatures and almost complete vacuum. This test is crucial for applications that need to function reliably under must function reliably under the most demanding conditions - be it in space space, aviation or special industrial scenarios.

Typical applications:

- Satellites and space components

- Permanent stress under space conditions

- High-performance optics and sensors

- Electronic systems for vacuum or high-altitude environments

Goal: Ensure functionality and durability under extreme conditions

Your technology - ready for use under extreme conditions!

Thermal vacuum cycle test

Rapid changes between heat and cold can put extreme strain on systems and materials. under extreme stress. The thermal vacuum cycle test simulates these dynamic conditions conditions, such as those that occur in orbit or in special terrestrial scenarios. scenarios. Ideal for testing system stability and material material behavior under realistic operating conditions.

Typical applications:

- Satellites and space probes (simulation of orbital conditions)

- Components for high-altitude flights or stratospheric balloons

- Testing of systems for extreme temperature cycles in industry

Goal: Testing material and system stability under repeated temperature changes

Changeable conditions? No problem - we ensure safety and reliability.

Flexible team

Do you have other requirements? Talk to us, together we will try to find a customized solution for you!

Downloads

Download the datasheet of our thermal vacuum chamber.

Contact

Contact us now and get your innovation safely into space or to another destination!